Material-handling

You can use a Raycus 50W laser to engrave stainless steel at a 90deg angle and with a speed up to 3,540 ipm.

Gulf States Saw & Machine Co. FM1212-50S can engrave acrylic and hard-plastic bricks, granite, marbles, tile, aluminum.

Fiber laser is a new type of laser cutting technology in the world that outputs a high-energy density laser beam and gathers it on the surface of the part to instantly melt and vaporize the area on the part irradiated by the ultra-fine focus spot and move the spot through the CNC controller. Irradiate the position to realize automatic cutting. Compared with the bulky gas laser and solid laser, it has obvious advantages. It has gradually developed into an important candidate in the fields of high-precision laser cutting, lidar systems, space technology, laser medicine and other applications.

Raycus is a popular laser source brand. This laser can be used by many different laser cutter, and engraver manufacturer. Raycus will appear in various places on the catalogs and websites of laser manufacturers. It simply means that all these machines have a Raycus Fiber Laser Technologies Co. Ltd. as their laser source.

Mirror galvanometers are a group of mirrors located in the laser head. They move very quickly to alter the path of laser engravers. A 10 degree rotation at the head can produce 1 3/4 inches of movement at 10 inches. It can also be used for tracing the laser paths, before engraving or cutting.

3D laser cutting systems offer the ultimate in accuracy and flexibility for users across a wide range of complex laser applications.

You can use a Raycus 50W laser to engrave stainless steel at a 90deg angle and with a speed up to 3,540 ipm.

Gulf States Saw & Machine Co. FM1212-50S can engrave acrylic and hard-plastic bricks, granite, marbles, tile, aluminum.

With the increase in the power of laser cutting lasers, laser cutting is developing from light industrial thin plate processing to focusing on industrial thick plate cutting, and due to the improvement of high-power laser beam mode and the application of 32-bit microcomputers, it is a fiber laser cutter equipment. High speed and high precision create favorable conditions.

Refraction bends light in an optical fiber laser. The optical fiber cable passes light through an opaque silica glass core that is impure and transparent. Cladding is a layer of silica that has been doped with other materials to reduce its refractiveindex. The core-clad interface will reflect light due to the difference in their refractive index.

Some PVC-based acrylics can release toxic fumes if they are heated. It is better that you check the chemical compositions before engraving.

Capable of very quickly measuring or reverse-engineering flat parts which have been manufactured on laser, plasma, and waterjet cutting systems, as well as punched and some stamped parts, MC Machinery�s inspection systems are exactly what your floor needs to put the fine in micro-fine.

Triumph Laser provides a computer, rotary axis, foot switch, 200mm lens, laser goggles, and a wrench set with the 30W desktop fiber laser.

MCWlaser PRO comes in half pre-assembled fashion. First, you must fix the vertical column connecting the laser source and laser engraver modules.

Laser cutting machines are able to cut metal with great precision. This is the main reason they are so popular. Plasma cutters can be cut with 2X greater accuracy than laser cutting machines. Plasma lasers can be used to cut metals with a precision of 0.1mm, or.004 inches. Laser cutters can cut metals at a precision of.05mm to.002 inches.

With laser, the real value comes from your production speed. If you can cut many parts in less time, you will get more money in return for time invested. So, if your production rate is high, a laser machine can still be great even though it has high operating cost.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.

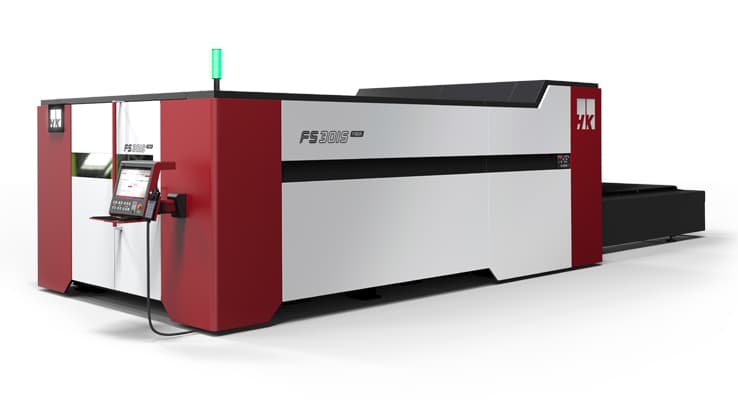

Laser fiber cutting machine

Fiber optic laser cutters are intended to cut metal at high speeds and with pinpoint accuracy. These machines, which have been on the market for more than 20 years, also use a fiber laser power source.

Thin carbon fiber mat can be cut with some fraying - but not when coated. The laser can cut or etch. The laser can cut materials such as wood, paper, cork, and some plastics.